Manufacturing Data Engine

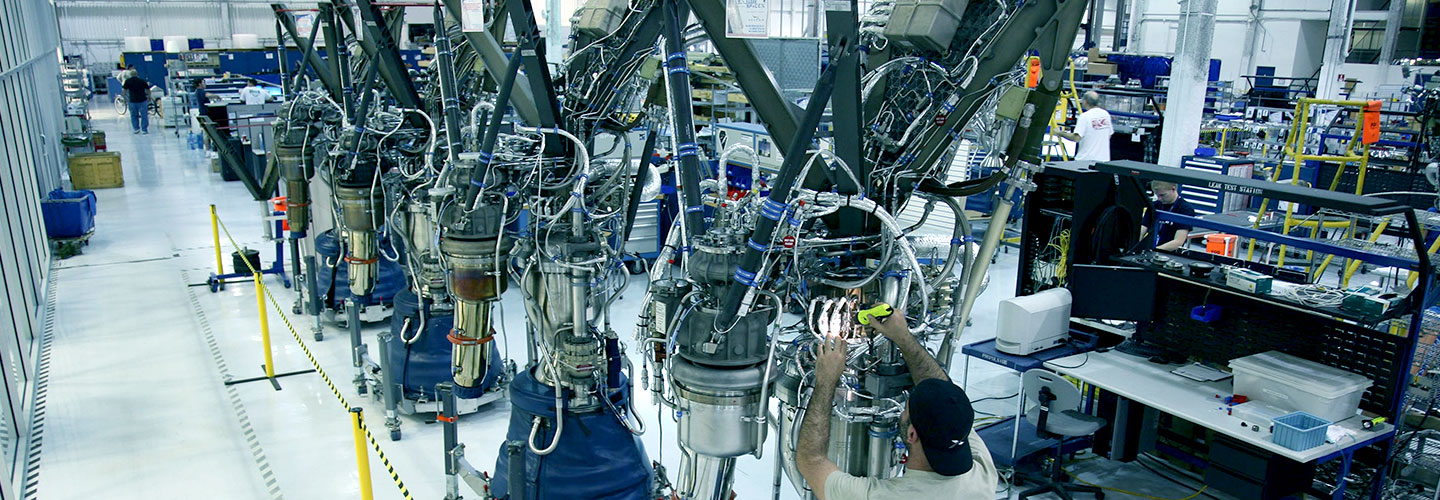

Leverage the Latest Cloud Architecture to streamline manufacturing operations

Supporting the construction and operation of a data infrastructure specialized for the manufacturing industry

Manufacturing Data Engine (MDE) is a cloud solution provided by Google Cloud that serves as the infrastructure for processing, contextualizing, and storing factory data.

It enables data-driven business activities by storing various types of data scattered throughout the factories in the cloud.

DATUM STUDIO utilizes MDE to visualize the data within factories. In order to streamline various factory operations such as production management, quality control, maintenance management, inventory management, as well as to sophisticate the management decisions, we comprehensively support everything from the construction of a data platform specialized for the manufacturing industry to its subsequent operation.

Real-time and scalable manufacturing data infrastructure

MDE has outstanding functions as data infrastructure dedicated to the manufacturing industry. It processes large volumes of manufacturing data in factories in real time and has the scalability to flexibly respond to increases in data volume.

In addition, sensor connection and registration can be completed with simple operations on web screens, and it is possible to connect without additional development by going through Manufacturing Connect edge (MCe), a dedicated edge computer operating system with over 250 drivers.

When installing sensors in a factory, the factory environment can be updated without downtime because it is not necessary to build a system to store data.

Advanced data utilization supporting rapid management decision-making

MDE creates new value by centralizing not only IoT data but also production management, inventory, and KPI information obtained from ERP and MES.

By building data infrastructure that accumulates all kinds of data and configuring data marts according to usage and purpose, we accelerate and streamline the utilization of data within companies.

For example, we seek to increase efficiency and make improvements through demand forecasting and inventory optimization based on order information, analysis for quality improvement by crossing the history of defective products with sensor information, detection of signs of failure by crossing production information with sensor information, and sophistication of management decisions by providing a dashboard that visualizes integrated information on the entire factory.

In addition, MDE enables not only the realization of rapid building with templates specifically designed for factory solutions but also flexible customization to match customer application. Its flexible architectural design meets the strict standards required by factories, where stable operation is essential.

For the security standards required in factories, utilizing a variety of services provided by Google Cloud realizes a security environment that complies with regulations through encryption of communication paths, restriction of access, and the building of a security monitoring system.

Furthermore, in cases where high availability is required, customization to ensure stable operations through automatic creation of backups, monitoring of system status, and establishment of a multi-region configuration is possible.

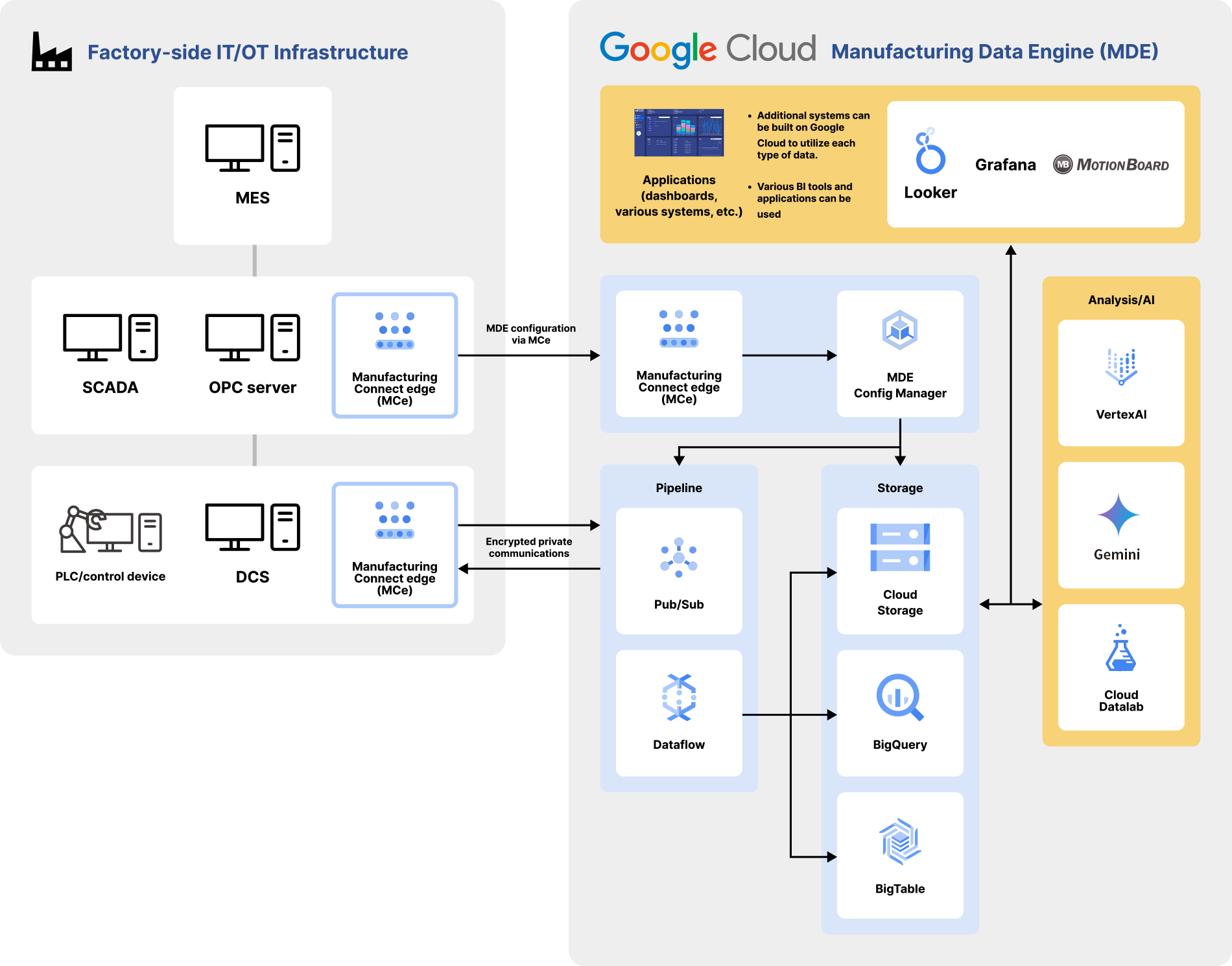

Overview of factory architecture using MDE

MDE is a solution using Infrastructure as Code (IaC) to manage system architecture configured on Google Cloud.

It enables rapid building of complete data infrastructure and flexible design matching customers’ detailed requirements.

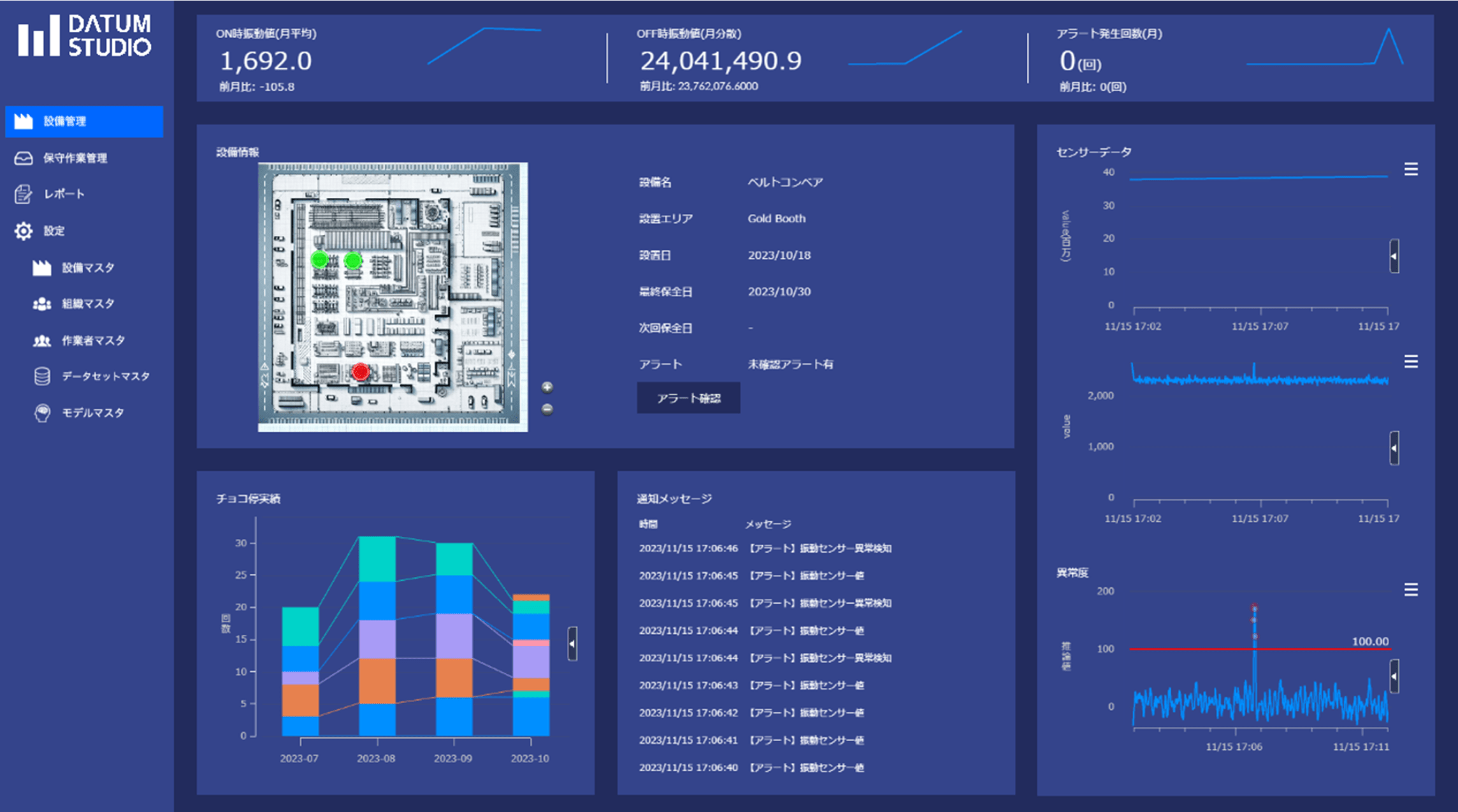

Rapidly build factory applications

MDE can be used to develop applications quickly by using Google Cloud services.

By leveraging Google Cloud’s AI ecosystem, customers can build their own AI applications at low cost.

DATUM STUDIO provides Factory Condition Manager, a maintenance management support system that runs on MDE. This allows customers to promote data utilization immediately after the data infrastructure is built.

Factory Condition Manager product page

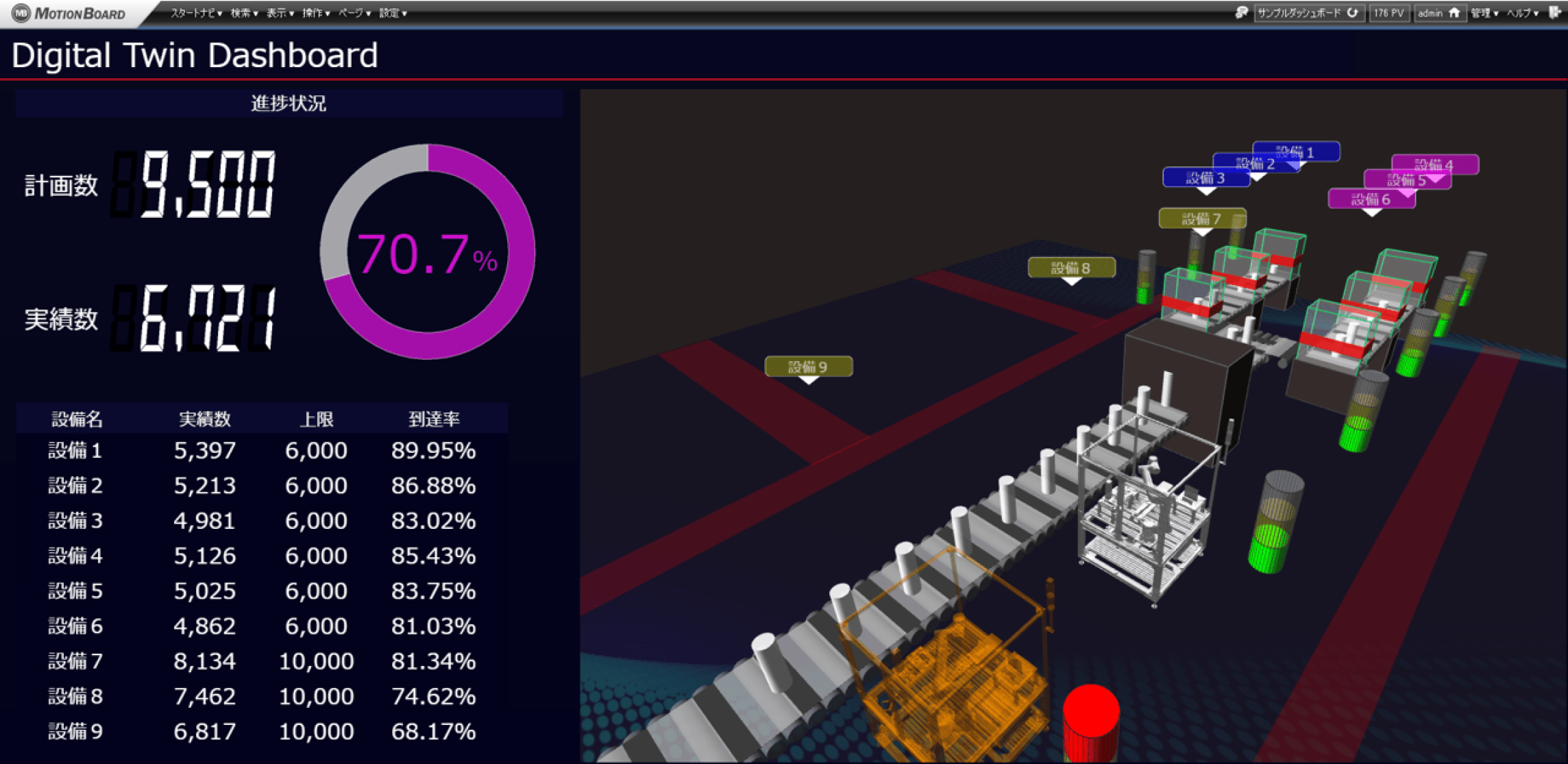

Supporting digital twins by linking with MotionBoard

MDE also provides a framework for realizing digital twins by linking with MotionBoard, a business intelligence dashboard provided by WingArc 1st Inc.

MotionBoard excels in 3D modeling and camera linkage, and visualizes the status of production sites in real time.

It is also highly customizable, making designing dashboards that match the configuration and workflow of each factory a simple task.

Support for MDE implementation

DATUM STUDIO provides support services for implementation of MDE.

We provide one-stop support from review of business processes and existing systems in factories and formulation of strategies based on data utilization to design and building of data infrastructure and operation and improvement after implementation.

Assessment phase

- We investigate current business processes, existing systems, data generated in business, constraints in system development and strategies for data utilization, and conduct assessments from data infrastructure building to its utilization.

System concept

formulation phase

- Along with additional systems for data utilization, we comprehensively develop a system concept, including data infrastructure building.

- We also consider system linkage across multiple sites within the company.

System design and

building phase

- We design and build MDE according to the requirements of each company.

- We can design and build not only data infrastructure but also data utilization systems at the same time.

Operation and

improvement phase

- We continuously provide support for system operation.

- We provide support for overall data utilization, including data utilization and analysis, and new system building.

Google Cloud is a trademark of Google LLC.

Team comprising over 100 data scientists Proven track record across industries and sectors

DATUM STUDIO has a team of more than 100 data scientists and a proven track record of using AI in the resolution of management issues for companies in a broad range of industries and sectors. To help you achieve your business goals, we can flexibly respond to needs from problem identification to planning for optimal data utilization, proof of concept (PoC), infrastructure building, AI model construction, continuous integration (CI), continuous delivery (CD), and continuous training (CT).