Cloud-based Maintenance Management Support System

Businesses with factories and manufacturing sites incur and bear significant running costs for equipment management.

In recent years, a trend of shifting to and introducing Condition-Based Maintenance (CBM), which prevents equipment failure by optimizing the timing of maintenance based on sensor information, while aiming to reduce costs and improve the operating rate of equipment, has intensified mainly among manufacturers seeking to establish smart factories.

DATUM STUDIO offers Factory Condition Manager as an AI solution for the purpose of providing support for maintenance management.

It has various functions such as visualizing sensor information stored in the cloud, as well as formulating equipment maintenance plans and automatically preparing reports for monitoring factory operating conditions.

Factory Condition Manager automatically detects anomalies in equipment and supports the equipment maintenance operations of customers, including maintenance decision-making.

CASE 1

The system is regularly maintained, but it is unclear whether the maintenance is performed at the appropriate time. Want to avoid unnecessary system shutdowns.

▼

Introduced automatic AI-based monitoring through which the frequency and scope of regular maintenance are optimized, costs are reduced and defects are detected without failure.

CASE 2

Sensors are installed to detect anomalies, but the status management of equipment is conducted by individual departments and knowledge is not shared throughout the entire factory. Want to manage data for the entire factory.

▼

Introduced customized data infrastructure with consideration given to on-site management and operation. It can be built quickly at low cost.

CASE 3

Monthly reports are prepared to ascertain the operating status of equipment, but the number of man hours of personnel preparing reports is too high.

▼

Implemented a function to automatically prepare monthly reports using LLM.

List of Functions

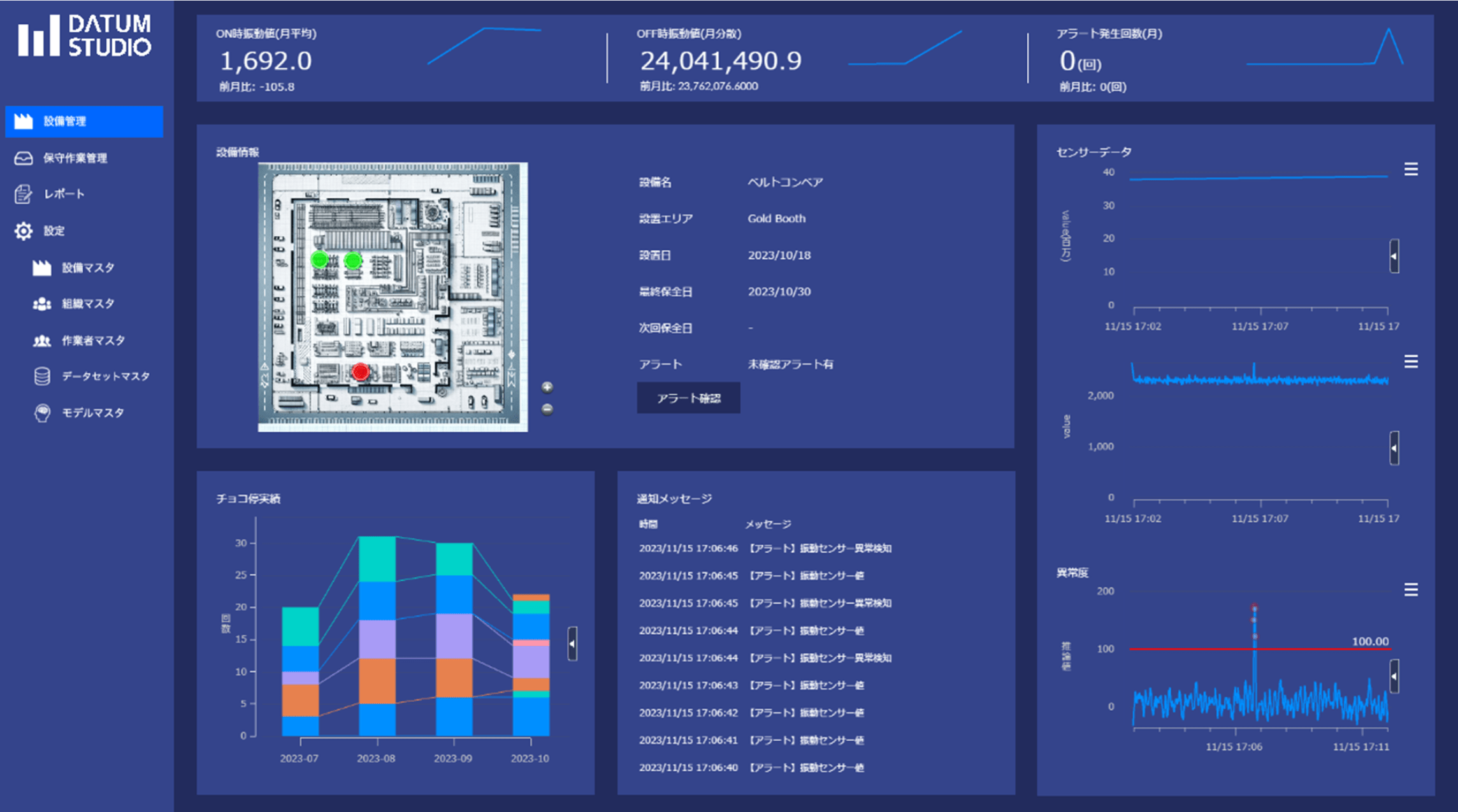

Dashboard for centralized management

This provides an interface menu for centralized management of plant equipment, sensor values, work schedules and other items. It can be accessed via a web browser, enabling monitoring also from smartphones and tablets.

Automatic AI diagnosis

AI automatically diagnoses whether there are any equipment anomalies based on sensor information. An AI can be easily built from the dashboard.

Alerts on equipment anomalies

A function for automatically sending notifications when an anomaly is detected. Notifications can be sent to e-mail, internal SNS, IoT devices in the factory, etc. and configured according to the application.

Scheduling for maintenance management

The schedule management function for inspections, maintenance, etc. enables seamless execution, from checking equipment status on the dashboard to scheduling inspections and maintenance.

LLM-based automated report preparation

Monthly reports are automatically prepared using a large language model (LLM). They are prepared by detecting anomalies in equipment, recommending maintenance implementation and even examining the causes of anomalies.

Provision of secure data management

System security measures are fully implemented for customers by restricting access and encrypting data. Highly confidential data is strongly protected from threats.

Descriptions of Functions

Dashboard with excellent operability and visibility

Factory Condition Manager collects data from sensors attached to equipment and provides a dashboard for visualizing factory conditions. Changes in the sensor data, the timing and cause of equipment stoppages and history of trouble can be centrally managed and checked.

The dashboard is provided as a cloud-based application, enabling decision-making based on data from the manufacturing site, even in offices located far from the factory or at overseas sites.

Easily build anomaly detection models

Factory Condition Manager makes it easy to build AI-based anomaly detection models with a few clicks. The anomaly detection models that are built enable users to ensure that high-risk anomalies are not missed and can be handled without failure.

Automatically prepare reports using LLM

The number of pieces of equipment and sensors becomes huge in proportion to the size of the factory, and in many cases reports prepared by the personnel in charge at the manufacturing site may be used to grasp the situation because it is difficult to grasp the full extent of the situation simply by managing and operating the equipment and sensors from a dashboard.

Factory Condition Manager uses a large language model, a type of technology that has been increasingly adopted around the world in recent years, to automatically prepare reports. It outputs information that can be used for decision-making in management, based on multiple sensor information associated with the equipment and device information related to the equipment. For example, the following information can be included in reports.

・Important KPIs for the factory

・A list of equipment with anomalies

・A list of maintenance actions and inspection items for equipment with anomalies

・Observations on the cause of anomalies

Providing data infrastructure for factory-wide data management

Factory Condition Manager is a cloud application that runs on the Manufacturing Data Engine (MDE), a factory data infrastructure building service provided by Google Cloud. MDE enables customers to quickly build a data infrastructure even if they have installed sensors but are not yet able to manage the data. MDE is an edge solution that supports more than 250 communication protocols to retrieve data from the factory equipment as a whole, enabling customers to reach data utilization with minimal maintenance of the factory environment.

DATUM STUDIO also supports the building of data infrastructure using MDE.

Manufacturing Data Engine (MDE) service page

Google Cloud is a trademark of Google LLC.

Team comprising over 100 data scientists Proven track record across industries and sectors

DATUM STUDIO has a team of more than 100 data scientists and a proven track record of using AI in the resolution of management issues for companies in a broad range of industries and sectors. To help you achieve your business goals, we can flexibly respond to needs from problem identification to planning for optimal data utilization, proof of concept (PoC), infrastructure building, AI model construction, continuous integration (CI), continuous delivery (CD), and continuous training (CT).